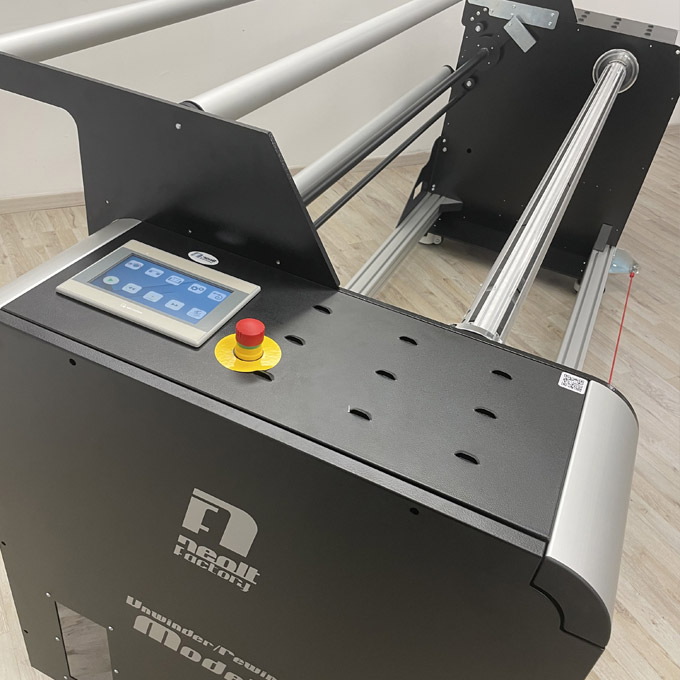

Model 4

Paper roll unwinder and rewinder

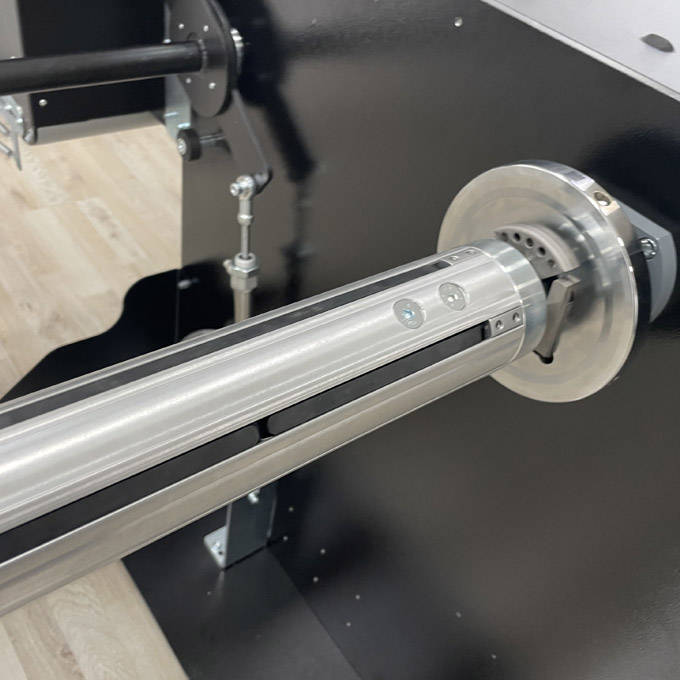

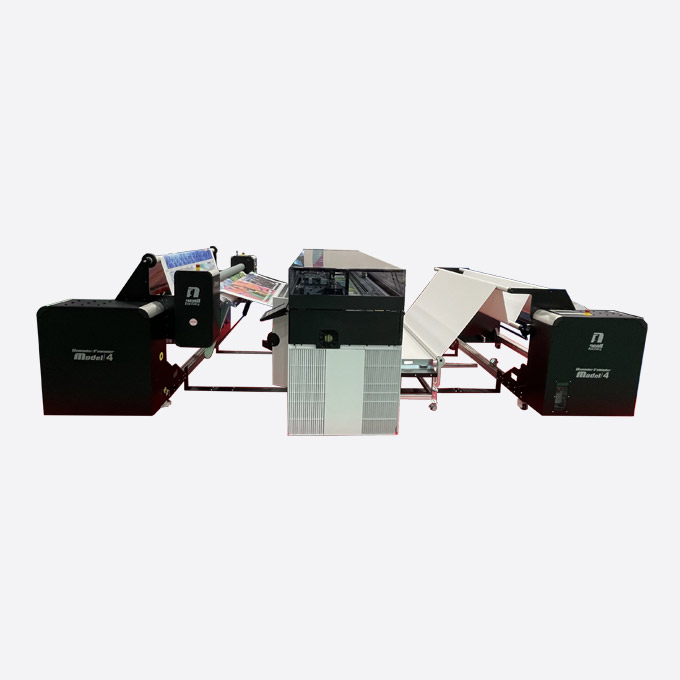

Unwinder and rewinders for paper rolls up to 500kg, independent, able to manage rolls of maximum length 1650 mm, designed for printing or cutting machines. Model 4 is also fully customizable: roll weight, length up to 5.2 meters and roll diameter are configurable to be able to provide the customer with the product he needs

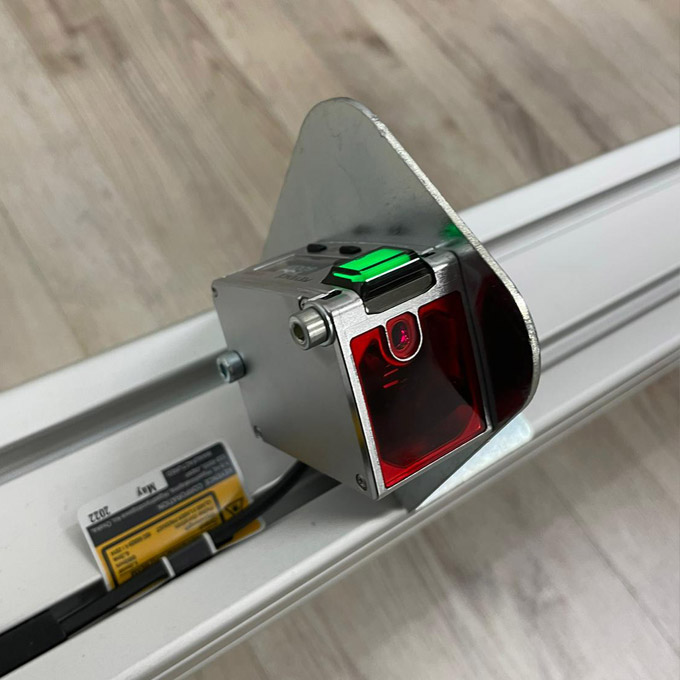

Possibility of using the unwinder up and down of cutting, printing or combined systems, maximum flexibility in the production configuration: with a single product you will have an unwinder or a rewinder depending on the dynamic production needs. In addition, a system that detects the position of the tensioner through optical sensors controls clockwise or counterclockwise the rewinder of the installed roll

Length

| on request |

Roll diameter

| on request |

Main features

- Length on request (stadard 1650mm)

- Max. reel diameter on request (standard 800 mm)

- Height on request

- Portata max su richiesta (standard 500kg)

-

Automatic speed management by analogic dandy roll

-

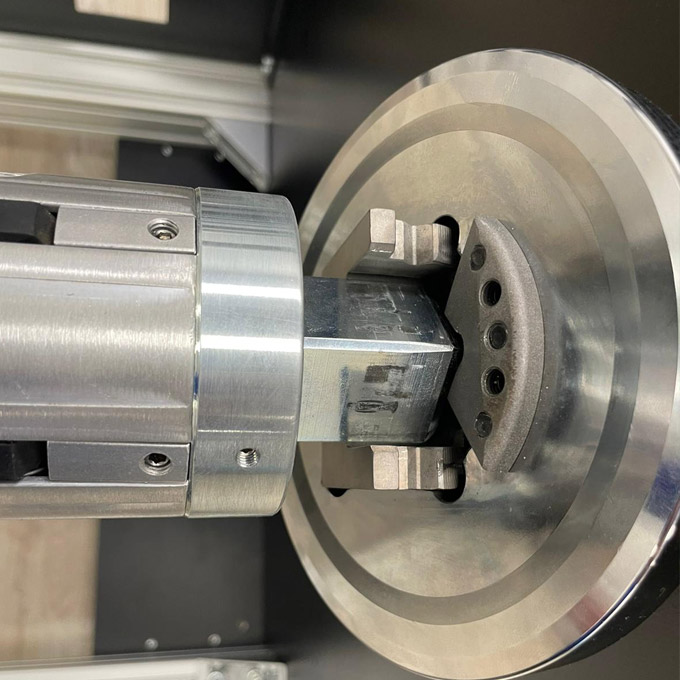

Pneumatic expansion roll holder shaft

-

Unwinder/winder

-

Easy loading of rolls by forklift

-

Roll Diameter Reading Laser Sensor

- Selector of rotation way

- 4 safety sensors on board of the machine

- Motorized by brushless motor

-

Touchscreen

-

Remote control

Optional

-

Configuration for online workflow with Canon colorado

Catalogues